As a micro-mechanical experimental method, CT technology enables real-time, non-destructive detection of internal material structures, providing reliable graphical data for the study of micro-damage models. The observation and description of crack evolution in geotechnical materials using this technology enhance the value of indoor rock mechanics tests and are significant for establishing constitutive relationships of geotechnical damage. With the development of CT technology and various disciplines, it has been applied in the detection and analysis of frozen soil, ice, rocks, and various composite materials.

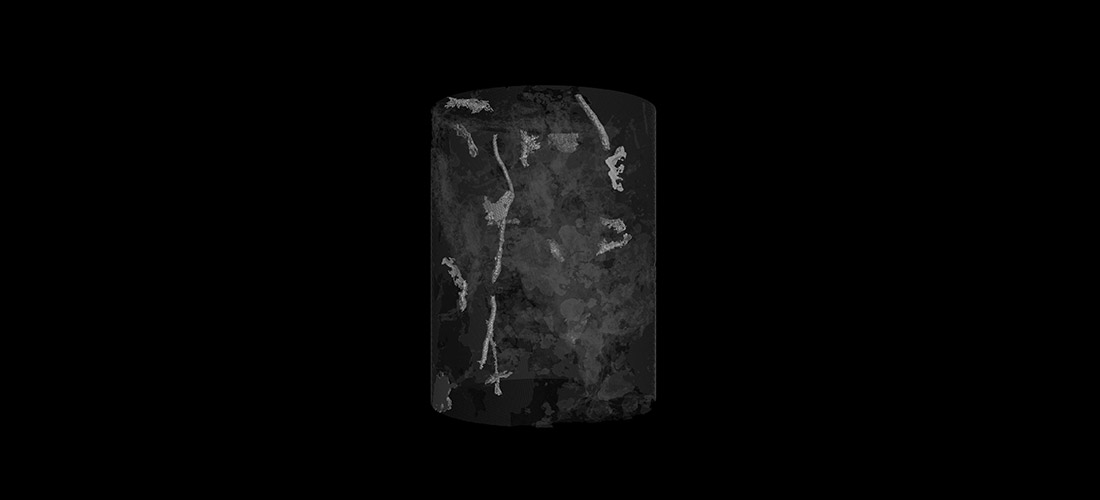

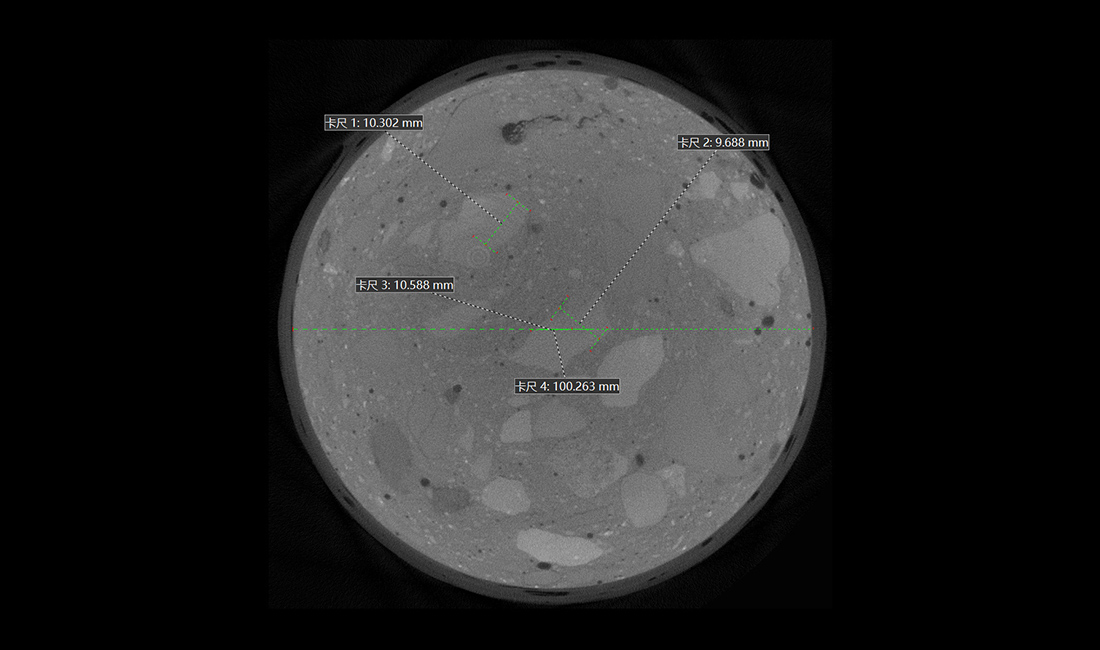

Rock - Crack Analysis

As a typical natural heterogeneous geotechnical material, the fracture evolution mechanism of rocks has always been a hot topic in rock mechanics and engineering. Using TOMO CT technology, high-resolution scanning tests were conducted on samples to obtain the distribution of internal and external cracks, further revealing the relationship between internal and surface cracks in failed samples.

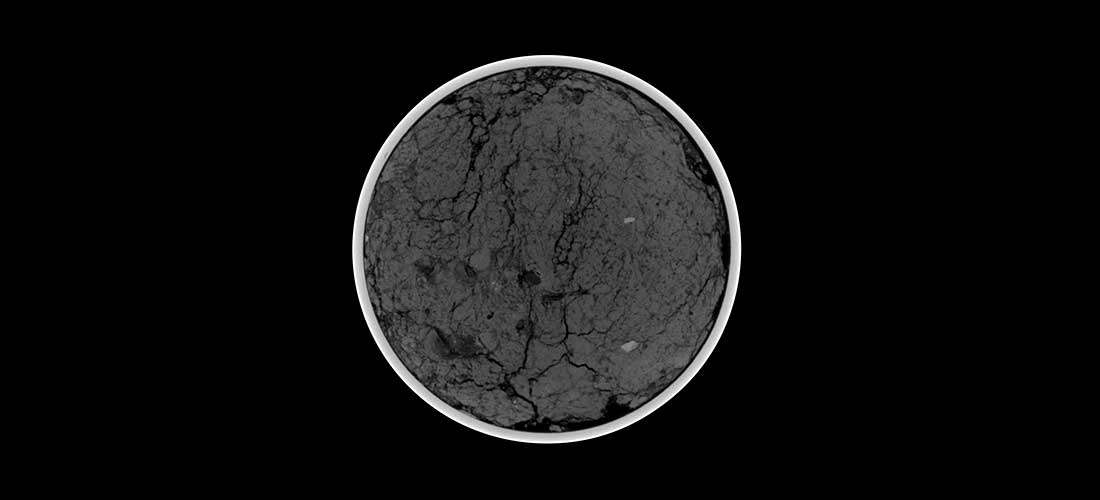

Soil - Pore Extraction and Analysis

Soil porosity is an important physical property of soil structure, determining the availability of oxygen and moisture, thereby affecting gas exchange and crop yield. Using various CT technologies, soil structural characteristics at multiple scales, such as soil aggregates, clods, and soil bodies, can be studied, including porosity, pore number, pore size, pore shape, fractal dimension, anisotropy, and tortuosity. This helps analyze the relationship between soil structure and physical, biological, and chemical processes at different scales.

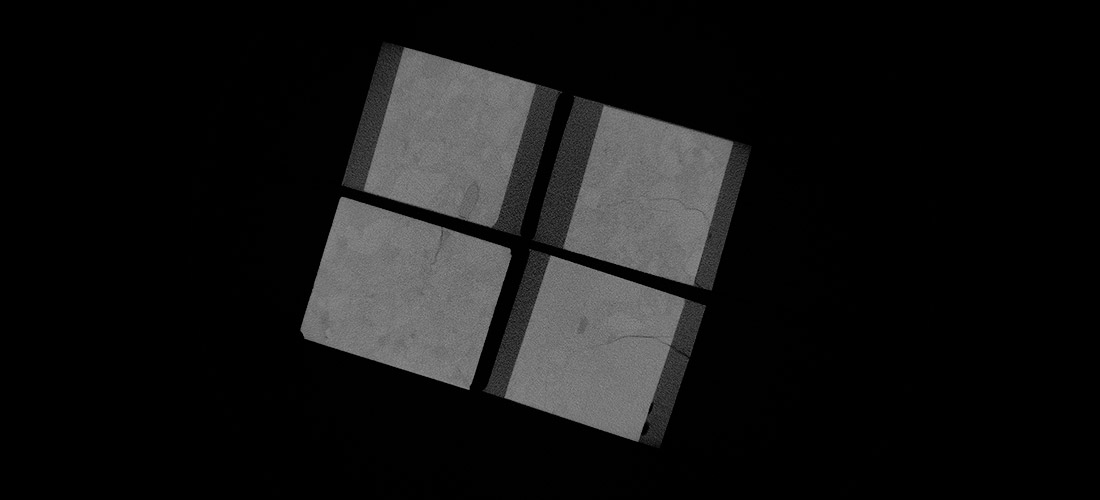

Concrete - Aggregate Analysis

Concrete aggregates and pores are critical factors affecting its mechanical strength. Using TOMO Industrial CT, the performance of aggregates and mixed fibers in terms of concrete porosity and fiber distribution characteristics can be evaluated, providing deeper insights into the mechanisms by which aggregates influence concrete strength.