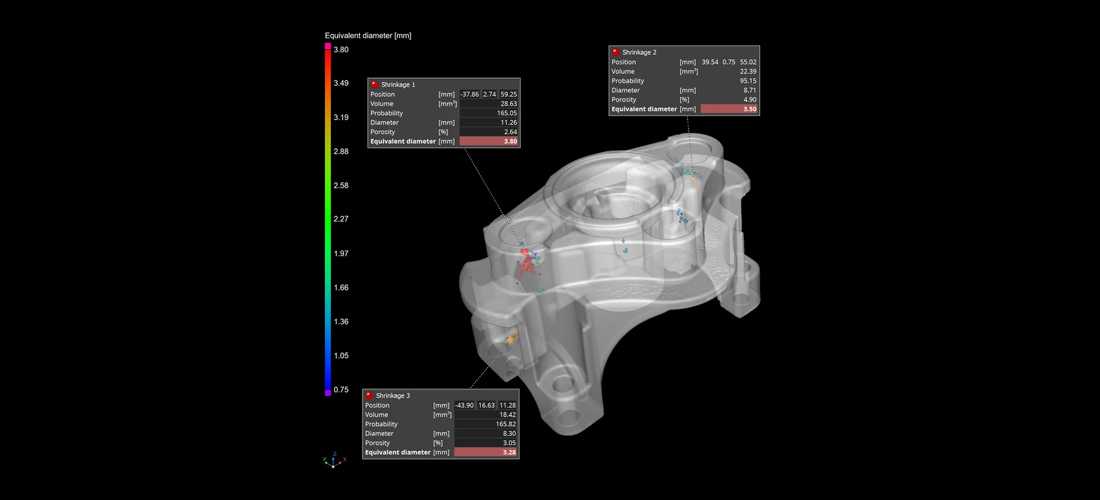

Tomo Industrial CT helps manufacturers address the most challenging non-destructive testing issues in additive manufacturing. Typical defects from powder bed fusion metal additive manufacturing processes, such as porosity, lack of fusion, balling (from liquid metal surface tension), excessive surface roughness, and microstructure issues, can all be detected by Tomo Industrial CT. Identifying these issues can save time and improve productivity.

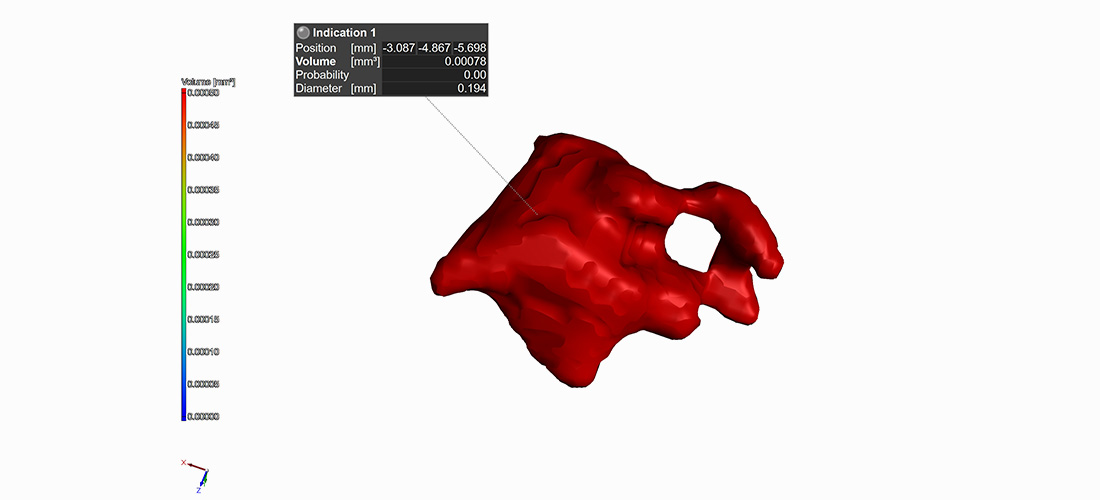

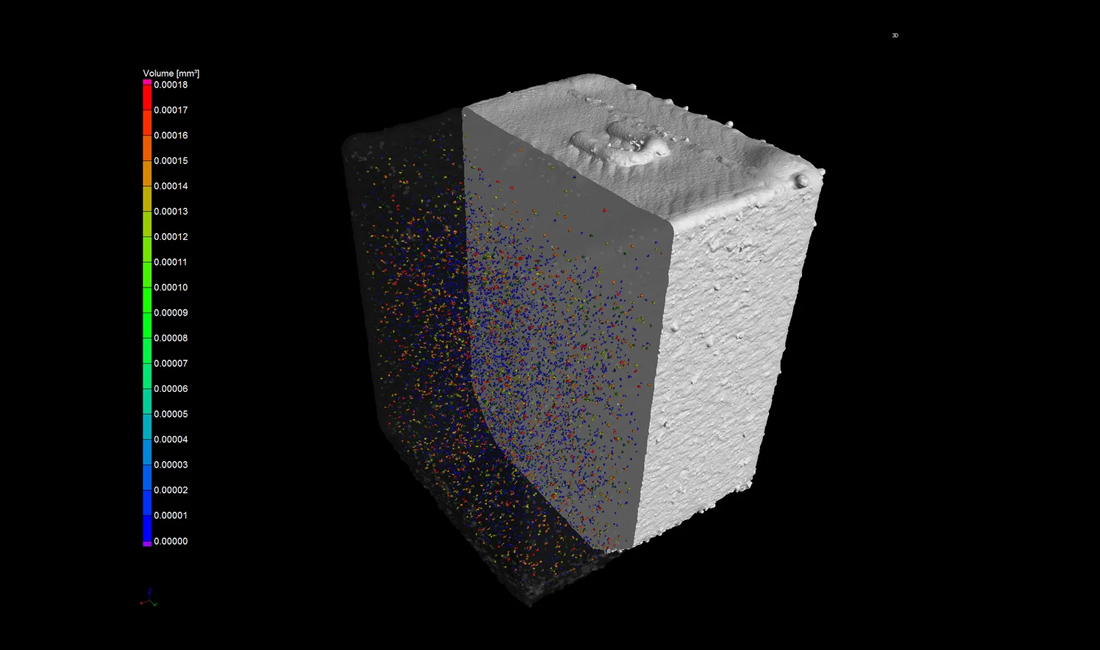

3D Printed Metal - Porosity Analysis

Laser additive manufacturing uses high-energy laser beams as the energy source to melt and prepare high-entropy alloys. It not only achieves a perfect combination of high strength and high ductility but also enables the production of larger, more complex, and high-temperature-resistant high-entropy alloy parts for engineering applications. Refractory high-entropy alloy additive manufacturing technology is a critical component of aero-engine development and is widely used in the aerospace industry.

In the additive manufacturing industry, Tomo Industrial CT is often used for the following aspects: metal powder hollowing, inclusion testing, internal porosity analysis, reverse engineering, model comparison, and geometric measurement.

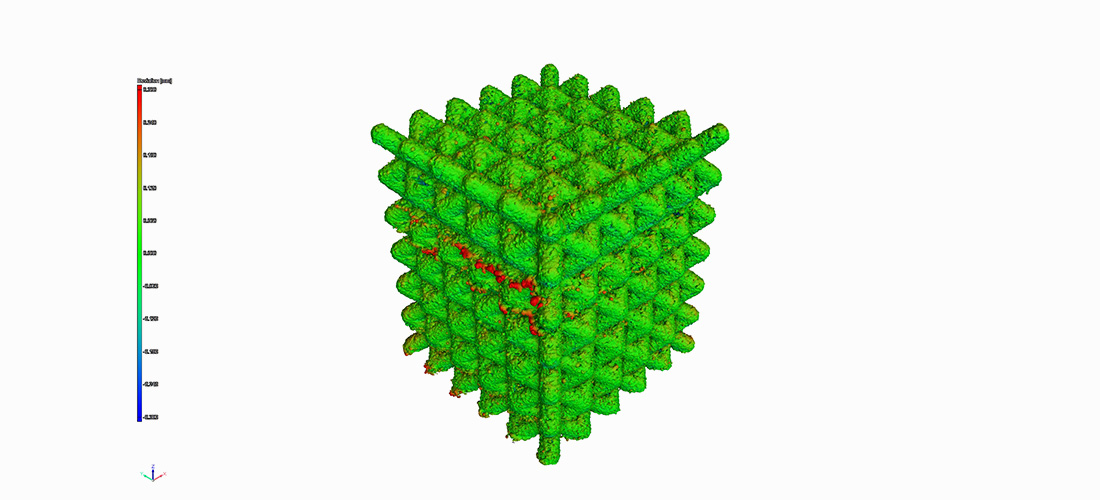

Titanium Alloy Printed Mesh - Model Comparison

Single Hole Morphology Analysis